GC3012F 6KW 12KW 30KW 40KW Big Size Ground Rail Type Fiber Laser Cutting Machine for Metal Sheet

Working area | 3000*6000mm/ 3000*12000mm/ 4000*14000mm |

Laser power | 1000W/ 1500W/ 2000W/ 3000W/ 4000W/ 6000W/ 8000W/ 10000W/ 12000W/ 20000W/30000W/40000W |

Laser source | MAX/ Raycus/ IPG |

Controller | Cypcut |

Motor driver | Japan FUJI/ Yaskawa servo motor driver |

Repeated positioning accuracy | 0.03mm |

Max moving speed | 80m/min |

Max acceleration | 1.0G |

Transmission | Rack and gear, double drive on Y axis |

Power consumption | <10kw |

Voltage | 380V, 50HZ/60HZ, 3 phase |

Features:

1. All IML-In mould label are safe and poison free with the international standard;

2. Multiple color patterns can be easily finished in one process;

3. You can add high values to the products to get vivid patterns and colors;

4. Strong adhesion and wear resistance after transfer printing, it can also increase the value of the product and strengthen the competitive ability of the market;

5. Widely used in food industry, paint industry, household industry etc.

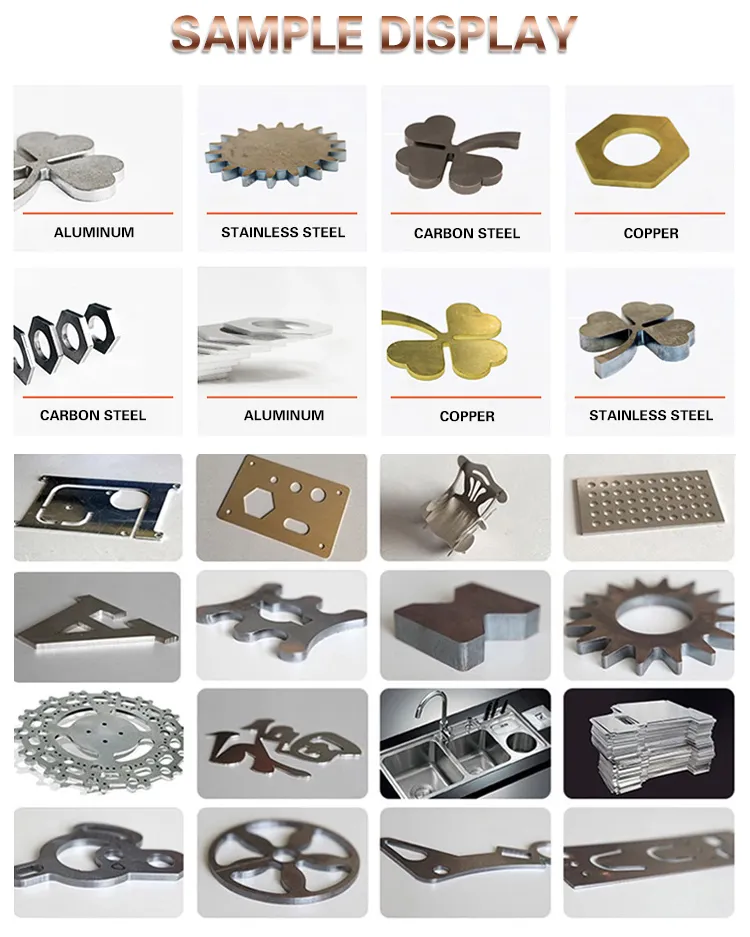

Product Application

Product Description

The series of pioneer GC-3012F laser cutting machine offers power ranges between 2000W to 40000W.

One of the most efficient machine technologies for rapid sheet metal cutting which can cut the thickness for 50mm or less.

1. Saving Material ---- CNC control, it can cut the material in different shapes, improve the utilization rate and reduce waste.

2.Easy Programme ----high accuracy, cut to shape without molding, smooth finish, eliminating the process for edge modification.

3. Save Investment for Molding ---- Laser cutting without molding, eliminating the cost for molding and repair, save time, resulting in less manufacturing cost, reduce the cost of goods sold, particularly suitable for processing parts in large-size.

4. Protecting Environment ---- working area for laser cutting is fully enclosed, low noise, is clean, safe, free of pollution, totally improve the working condition and environment.